Ideation and concepting- a way to create new things

A design assignment is usually based on definitions and a pre-assumed solution to the end result. Such an approach is appropriate when the objective has already been rightly defined. But what should be done when the target is to achieve something truly new? In this case you have to start through ideation and concepting.

What can be gained from this process?

If your target is to create a future and get rid of used thought patterns, you should focus on brainstorming without strict definitions. This provides answers to questions, such as:

- How can you stand out with design from your competitors?

- How could a product work in a new way?

- Are there any new solutions for manufacturability?

- How can product maintenance work more smoothly?

Ideas obtained through these questions are presented through different sketches, 3D models or test and scale models. This is useful for the collecting of comments from your staff or customers. The end result of the concept phase also serves as a guideline for the actual product design.

A cent paid is a euro saved

Experience has shown that early stage investments pay off. During the ideation phase, it is safe to study all ideas in order to get asssured of the right direction at an early stage. The further the concept is developed before the actual design work begins, the higher quality of products will be created.

A euro’s investment during the ideation phase may come to correspond to savings of 10 euros at the planning stage and even 100 euros if changes need to be made during the production phase.

How do you move forward?

Discuss with your team whether you have good definitions for developing a new product. If you feel that new and fresh ideas will refresh your own view with the new product, we can help. Contact us.

If your idea is clear in terms of the objectives, you can ask us for our view on the industrial design of the product.

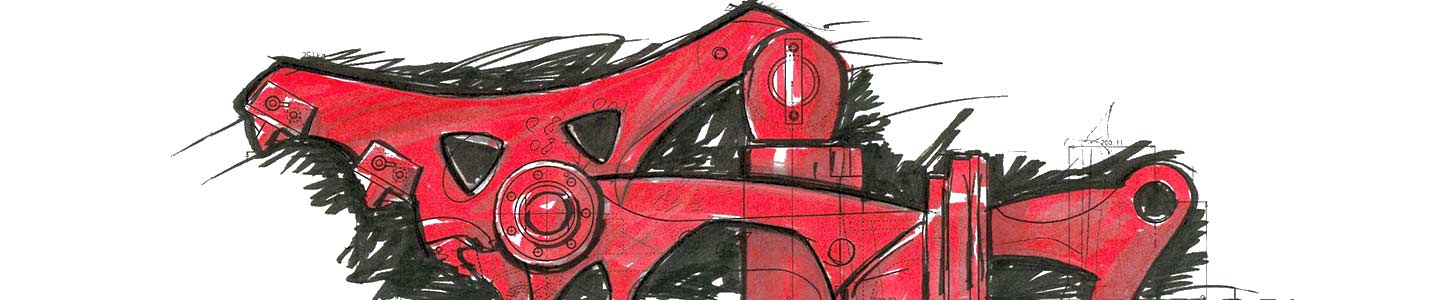

Examples of concepts we have carried out:

Control devices of work machinery

Our client wanted to upgrade their existing machine and add a new feature. We created concepts for possible solutions and implementation methods as sketch images and preliminary 3D models that were then printed out. The printouts were used to collect feedback from a test group of key customers and trainers in order to support the actual development work.

Operating principle of a pipe processing line

The client, for whom we had designed individual pipe handling equipment, wanted our vision on the operating principle of the pipe processing line. Based on our previous cooperation, our client expected a fresh approach and insights from the perspective of a non-process industry professional

Hollow-core slab modifier

Our client, a market leader in their field, wanted our out-of-the-box view of the design and operating principle of a concrete slab production machine. The ideas were presented as sketches and scale models.

Situations and possibilities of using cleaning equipment

We facilitated a workshop for our client in which to collect and brainstorm different use cases of a universal cleaning equipment for both cleaning and other uses. The brainstorming was carried out in a group consisting of personnel from marketing, product development, testing, assembly and packaging design, as well as, of course, the company’s management. The collected ideas served as guidelines for the actual conceptualization and design of the product. The initial effort helped to keep the project focused and to streamline it without unnecessary sprawl and additional requirements along the way.